“Whether you think that you can, or that you can’t, you’re usually right.”

-Henry Ford

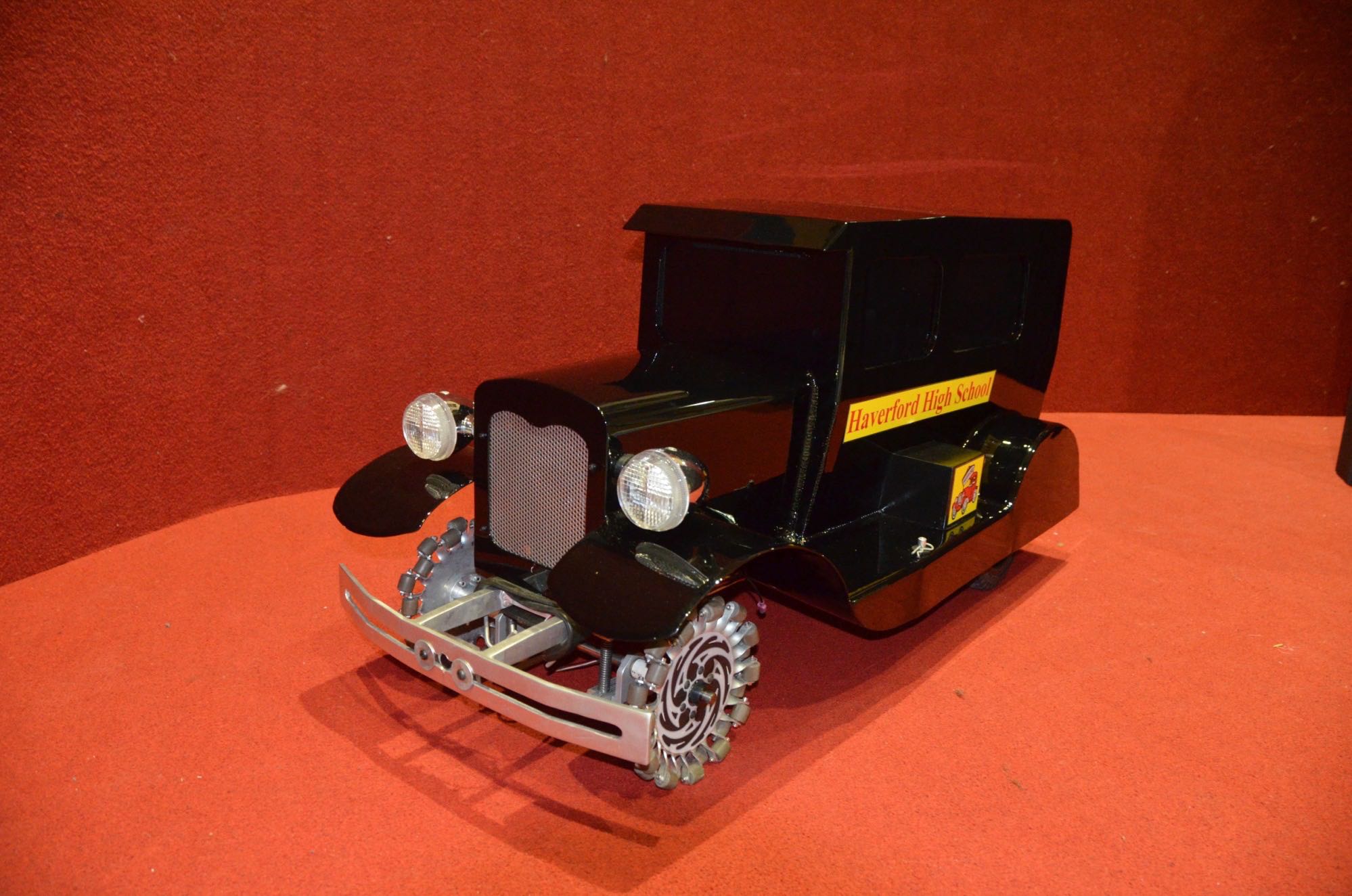

The 1929 Model A Ford is the mascot of Haverford High School. Symbolizing the determination and perseverance if its creators, the automobile serves as an icon for both the club and the school as a whole. However, unlike most schools, HHS had no physical representation of its mascot to parade at events and competitions. This is where the team decided to come in and help. In 2011, with the help of dedicated alumni, the club came together to build the most meaningful product ever produced by Team 484, Henry.

Henry is a miniaturized version of the Model A Ford. It features a beautiful chassis, motorized wheels, a horn, and lights and can wow the crowd with its exceptional wheelies. All in all, it is more than just a simple robot, it’s an art piece.

The construction of Henry began with the frame. Made of aluminum and filled with electronics, the frame is the structural backbone of our mascot. On the front of the frame is an ultrasonic rangefinder which can detect objects ahead and safely stop. This feature was a must when driving a heavy piece of metal around bystanders. In addition, a pair of omni-wheels are also mounted onto the front sides of the frame. These wheels have a series of rollers around them which allows the front of the robot to slide left and right, making turning far more power efficient. Working back to the middle of the frame you can find the horn and electronics. The horn is a very loud car horn that never fails to raise itself above the noise of the crowd. In addition, the electronics consist of speed controllers for powering the electric motors that power the rear wheels, a radio for communicating with a laptop that controls the robot, and a cRIO, a small embedded computer for controlling the functionality of the robot and interpreting commands from the driver. All these parts work together to bring the robot to life. Lastly, in the back of the frame is a wheelie bar. This bar has rollers on the end and is used to prevent the robot from tipping over when doing a wheelie.

The construction of Henry began with the frame. Made of aluminum and filled with electronics, the frame is the structural backbone of our mascot. On the front of the frame is an ultrasonic rangefinder which can detect objects ahead and safely stop. This feature was a must when driving a heavy piece of metal around bystanders. In addition, a pair of omni-wheels are also mounted onto the front sides of the frame. These wheels have a series of rollers around them which allows the front of the robot to slide left and right, making turning far more power efficient. Working back to the middle of the frame you can find the horn and electronics. The horn is a very loud car horn that never fails to raise itself above the noise of the crowd. In addition, the electronics consist of speed controllers for powering the electric motors that power the rear wheels, a radio for communicating with a laptop that controls the robot, and a cRIO, a small embedded computer for controlling the functionality of the robot and interpreting commands from the driver. All these parts work together to bring the robot to life. Lastly, in the back of the frame is a wheelie bar. This bar has rollers on the end and is used to prevent the robot from tipping over when doing a wheelie.

After the frame came the chassis. The chassis started out as a simple cardboard mock-up based on images of Model A Fords. Using cardboard allowed the team to tweak the design as needed until it looked just right. After that, it was time to make the real thing.

After the frame came the chassis. The chassis started out as a simple cardboard mock-up based on images of Model A Fords. Using cardboard allowed the team to tweak the design as needed until it looked just right. After that, it was time to make the real thing.  Aluminum sheets were bent and welded together to form the shape of the chassis. This was done by Vinnie Gallagher, of Weld Worx, Inc. Once the chassis had been bent and welded, the owner of Brendan’s Ltd., a local collision center, donated his time and resources to bring Henry to life with a shiny new paint job. This really brought Henry together and made him the symbol he is today. The students, the mentors, and the school community were all more than pleased with the generosity and quality of the craftsmanship.

Aluminum sheets were bent and welded together to form the shape of the chassis. This was done by Vinnie Gallagher, of Weld Worx, Inc. Once the chassis had been bent and welded, the owner of Brendan’s Ltd., a local collision center, donated his time and resources to bring Henry to life with a shiny new paint job. This really brought Henry together and made him the symbol he is today. The students, the mentors, and the school community were all more than pleased with the generosity and quality of the craftsmanship.

Henry was a great project for both our club and our school, and the club would like to thank all the people who contributed their time and effort to help us get this wonderful robot together. Our mentors and our team members, the painter, and the body worker all contributed many free hours of their time to help the club.

In order to make sure Henry could keep running for years to come, the team updated his control system in the Fall of 2019 to the newer version. The team even added a LIDAR sensor to the top of Henry to replace the ultrasonic sensor. This new sensor is safer because it has a wider field of view, which means Henry is less likely to accidentally run into someone.